Sorry. We did not find anything.

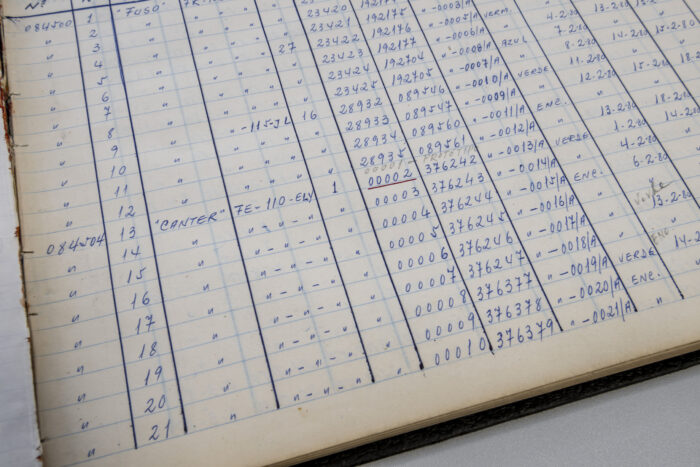

With the start of production of the current and latest series, eight generations of the FUSO Canter will be rolling off the production line at Mitsubishi FUSO Truck Europe in Tramagal, Portugal, from the beginning of 2022. The plant, located around 150 kilometres north-east of Lisbon, is FUSO’s central production facility in Europe and manufactures all Canters and eCanter for the European market.

CANTER PRODUCED

FROM 1980 TO NOW

OVER 50 PER CENT OF THE COMPONENTS COME FROM MORE THAN 90 EUROPEAN SUPPLIERS.

HIGHER GOALS.

ALL FOR SUSTAINABILITY.

As part of Daimler Truck AG, Mitsubishi FUSO Truck Europe is also committed to ambitious sustainability goals. The increased use of renewable and green energy sources and the adaptation of internal processes are important building blocks in the implementation.

ZERO EMISSIONS.

CO2 FREE PRODUCTION.

SOLAR ENERGY.

UP TO 350 MEGAWATTS.

GREEN HYDROGEN.

PRODUCTION ON TRIAL.

EMISSION-FREE LOGISTICS.

PURELY ELECTRIC FACTORY TRAFFIC.

LESS WATER.

OVER 60 % REPROCESSING.

MORE RECYCLING.

EXPANSION OF THE CIRCULAR ECONOMY.

OF SIGNIFICANCE.

LOCAL AND INTERNATIONAL INFLUENCE.

Tramagal currently employs 530 people from seven different nations. The company is the largest employer in the region. The production currently manufactures up to 15,000 units per year, and the plant can expand its capacity at any time. From Portugal, the vehicles go to 32 European countries, as well as to Morocco and the USA. Mitsubishi FUSO Truck Europe is a major exporter and Portugal’s third largest vehicle manufacturer.

GLOBAL STANDARDS.

FROM TRAMAGAL TO THE WORLD.

In addition to quality assurance in their own factory, the quality management experts from Tramagal also keep an eye on the standards in various international markets. As part of the “Global Excellence Program they visit the assembly plants several times a year in countries such as Morocco, Turkey, Egypt or Kenya, where FUSO exports the dismantled Canter and where it is assembled on site. There they are responsible for the recurring process and system audits. They also accompany all the necessary steps for quality release, such as documentation and training, when a new product is launched on the respective market.

The “Global Excellence Program” guarantees the highest quality standards in all Daimler Truck AG plants.